US Standard Full Port Design Bellows Globe Valve for Pharma/Fertilizer Pipelines Low Emission Type-Marine Supplies

US Standard Full Port Design Bellows Globe Valve for Pharma/Fertilizer Pipelines Low Emission Type-Marine Supplies

- Category: Other parts

- Views:76

- Product description:

Product Description

Application

Petroleum, chemicals, pharmaceuticals, fertilizers, electricity

Main advantages of the product

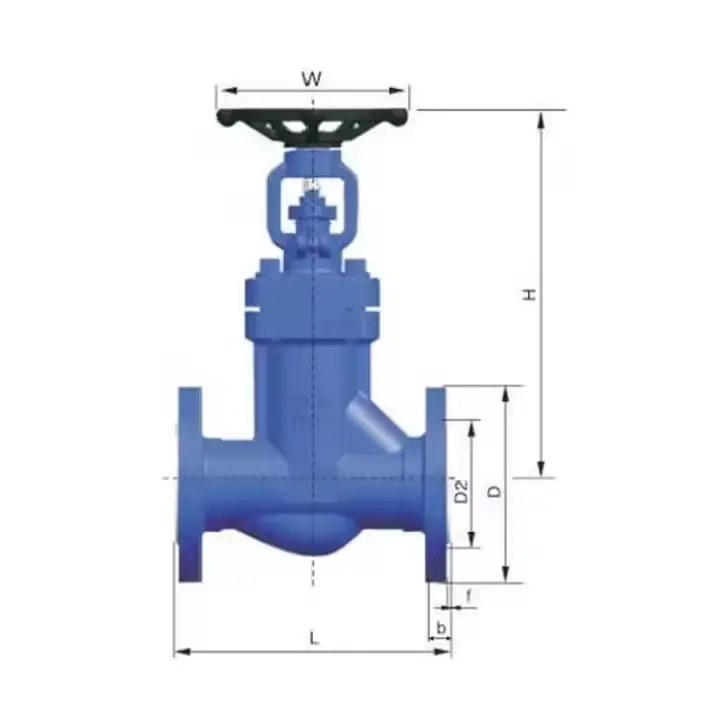

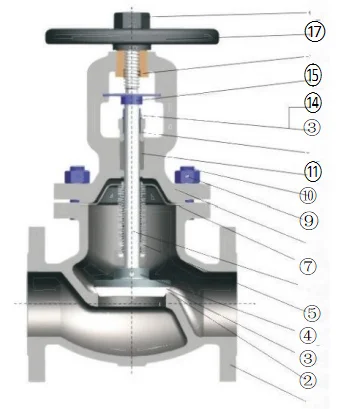

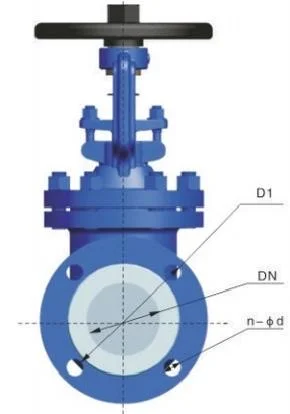

1. The bellows-sealed stop valve, whose key component is the metal bellows, is automatically rolled welded with the valve stem assembly at the lower end and the connecting plate at the upper end, forming a metal barrier between the fluid medium and the atmosphere to ensure zero leakage of the valve stem.

2. The valve disc adopts a conical design, and the sealing surface and the medium are streamlined, with better sealing performance and longer service life.

3. The double sealing design (bellows + packing) will prevent leakage if the bellows fails, and it meets international sealing standards.

4. The valve cover is equipped with a grease joint, which can directly lubricate the valve stem, nut and sleeve, unlike the traditional method of only adding lubricating oil to the thread.

5. The ergonomically designed handwheel has a longer service life, easy and convenient operation, and is safer and more reliable.

2. The valve disc adopts a conical design, and the sealing surface and the medium are streamlined, with better sealing performance and longer service life.

3. The double sealing design (bellows + packing) will prevent leakage if the bellows fails, and it meets international sealing standards.

4. The valve cover is equipped with a grease joint, which can directly lubricate the valve stem, nut and sleeve, unlike the traditional method of only adding lubricating oil to the thread.

5. The ergonomically designed handwheel has a longer service life, easy and convenient operation, and is safer and more reliable.

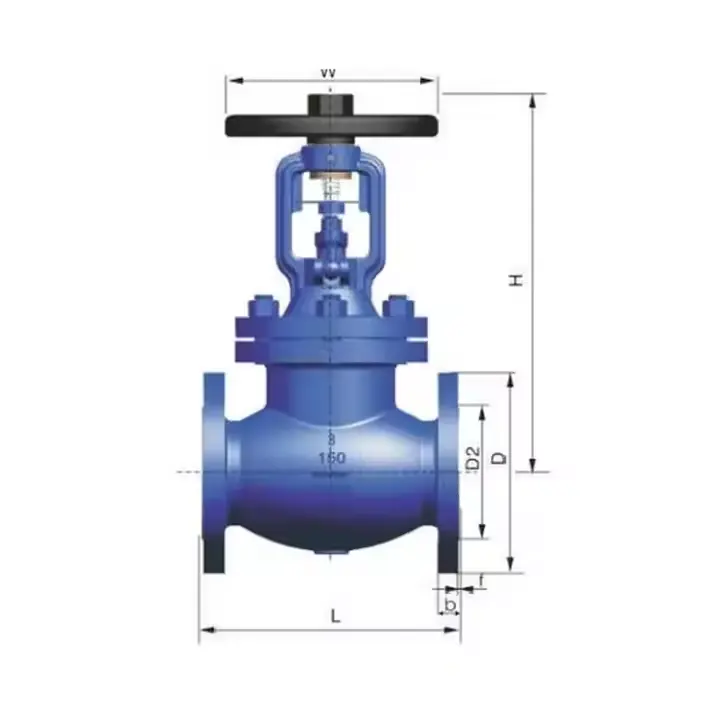

Specification

Technical Specifications

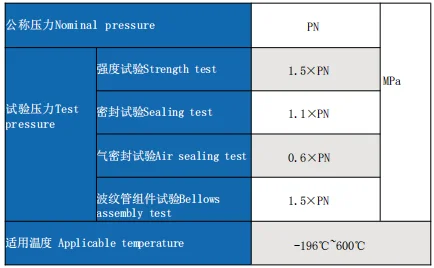

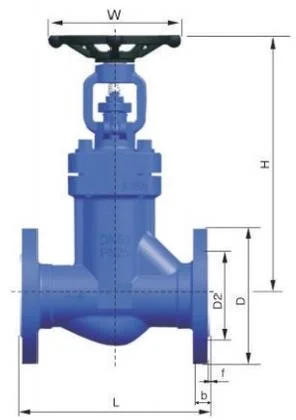

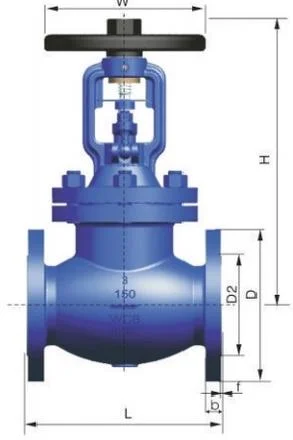

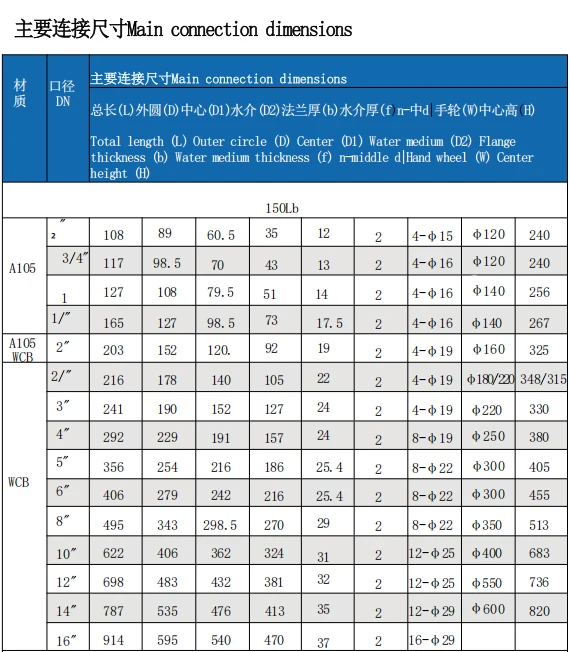

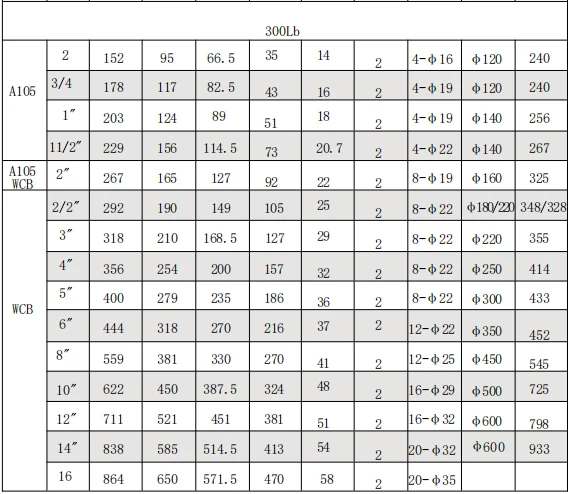

Design standard: ANSI 16.34

Structural length: ANSI B16.10

Connection flange: ANSI B16.5

Test and inspection: API 598

Structural length: ANSI B16.10

Connection flange: ANSI B16.5

Test and inspection: API 598

Performance Specifications

Main parts material

CATEGORIES

LATEST NEWS

CONTACT US

Name: Ada

Mobile:0086-13564780885

Tel:0086-21-36120339

Email: parts@sinooutput.com

Add:NO.258 Zhaojiabang Rd Shanghai 200031

- online service

close

- parts@sinooutput.com

- online service

close

- parts@sinooutput.com